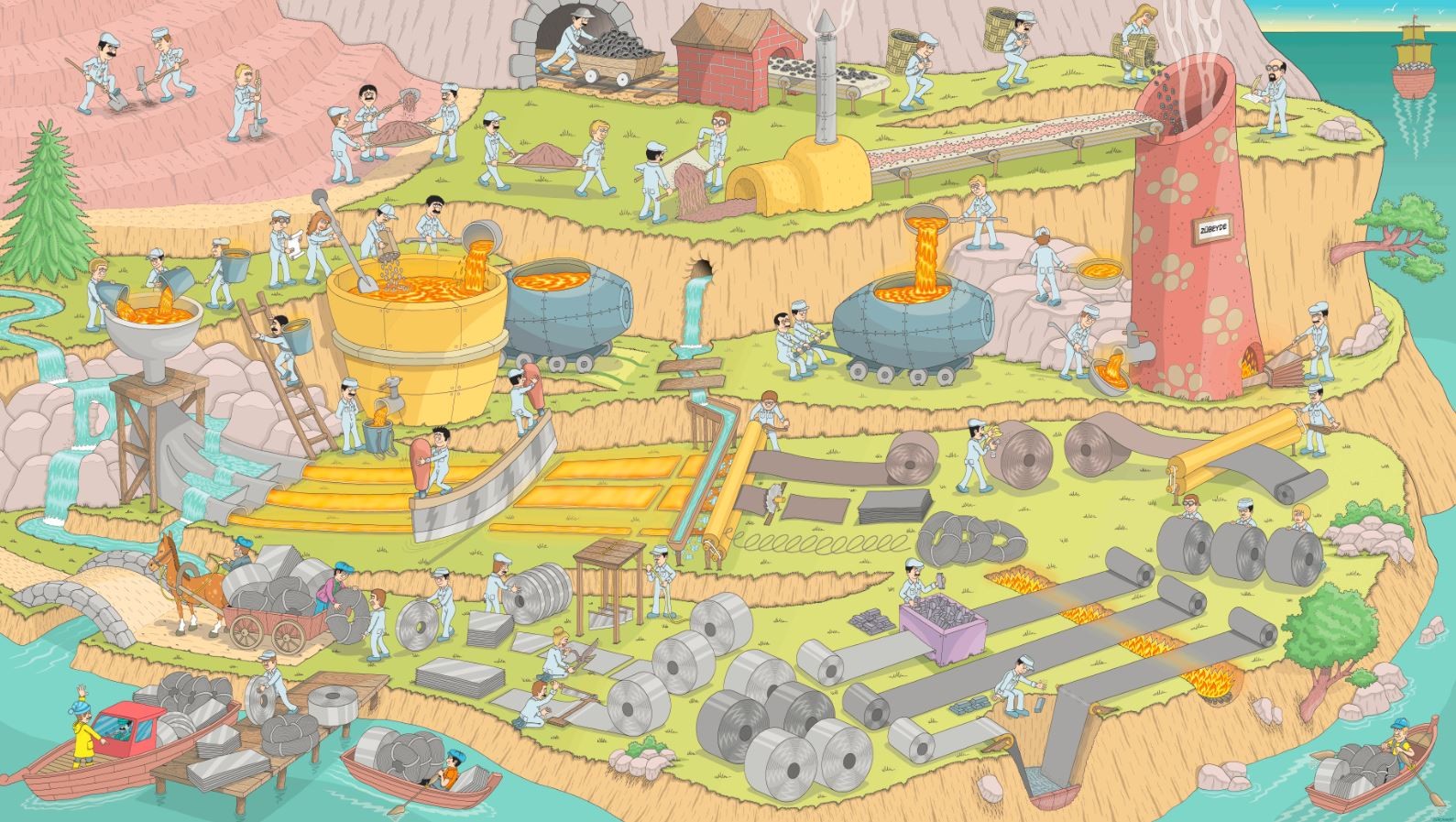

OYAK Mining Metallurgy, Turkey's global steel power OYAK Mining Metallurgy operates in a wide range of sectors, from iron ore to steel production and steel service centre services. As integrated steel producers, Erdemir and İsdemir provide added value to steel users in our country and around the world with high quality and world-class flat and long steel products.

The Story of Steel

-

01

The Beginning of the Story in Integrated Production

Iron ore and coal are the main raw materials shipped to Erdemir and Isdemir plants by sea and rail. Ermaden is one of the key source of raw material for the Group.

02

Arrival of Coal and Pellet to the Plants

Shipped to the coke plant furnaces via conveyor belts, coal is converted into coke under high temperature and in an oxygen-free environment. This is the procedure of manufacturing coke, deemed necessary by blast furnaces.

03

Coke Plant Furnaces

Production process commences, as the raw material is brought to the plants. Coal is shipped to the coke plants to be subjected to the coking process whereas fine ore is shipped to the sinter plant for the sintering process.

04

Sinter Plants

Sinter is produced after fine ore, iron flue dust/fine and oxide are dimensioned to a correct size at the sinter plants so that they can be utilized by the high blast furnaces. Subsequently, they are transferred to the blast furnaces via the conveyor belt system.

05

The Blast Furnaces

The blast furnaces produce liquid crude iron of which its production requires the use of iron ore, sinter, pellet and coke as the components. Liquid crude iron produced is kept in torpedoes after being cleared from slag.

06

Steel Plants

Liquid crude iron is transferred to the steel plant for the desulphurization treatment at the desulphurization plants. By making use of liquid crude iron, scrap and alloy elements varying in line with the desired quality, the carbon amount in the liquid crude iron is reduced by means of pure oxygen blowing method. Hence, liquid crude iron is converted into liquid steel..

07

Continuous Casting Plants

Liquid steel is then, interminably, casted into molds at the continuous casting plants. Subsequently, it is solidified at a desired size and converted into slabs or billets, which are semi-finished products.

08

Rolling

As for formed steel, the slabs are transferred to the hot rolling mills while the billets are transferred to the wired rod mill. The coils and sheets are flat steel products made from slabs, whereas, wired rods, a kind of long product, is derived from billets. Being Turkey’s only integrated plant producing both flat and long steel products, İsdemir produces billets and coils from high-quality and high-purity ore.

09

Products

Coils produced at hot rolling mill are rolled in cold rolling mill at room temperature. In this fashion, they are made thinner and a cold product is obtained. Furthermore, depending on demand, the cold rolled products are made into galvanized or tin-chrome coated steel utilized for packaging.

10

Journey of Products

The finished-products made at our plants are shipped to customers by road, rail or sea. The sized flat steel products ordered by customers are shipped subsequent to being subjected to the slitting and cutting processes at the Steel Service Centers (i.e. ERSEM) located in Gebze, İskenderun and Ereğli.